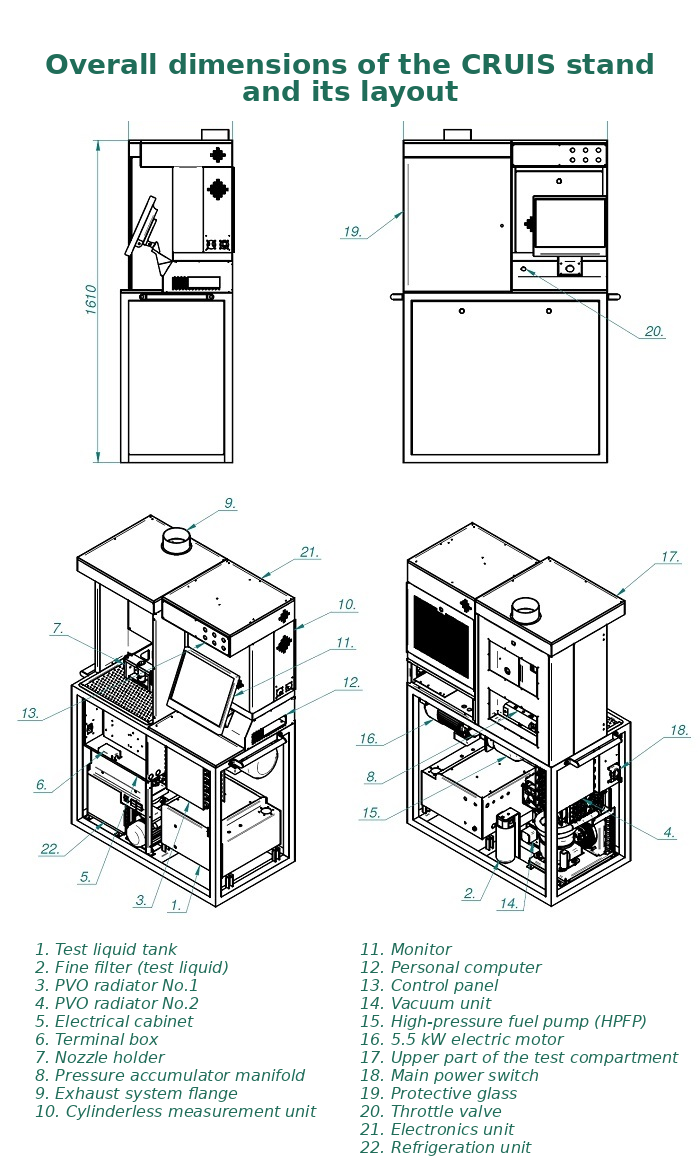

CRUIS — Common-Rail Injector testing and coding

The CRUIS 1-channel Test bench is designed for testing and coding Common Rail injectors manufactured by Bosch, Delphi, Denso, VDO Siemens, Cummins, AZPI, as well as HEUI Caterpillar unit injectors.

Tell us injectors you see most often — we’ll configure the bench for you.

Supported Systems and Technical Capabilities

- Injector coding support: Bosch ISA/IMA, Delphi C2i/C3i/C4i, Denso, VDO

- Built-in and editable manufacturer-specific test plans

- Digital storage and printing of test protocols

- Regular software updates for new injector types

- Common-Rail injectors from Bosch, Denso, Delphi, VDO Siemens, Cummins, AZPI, as well as HEUI Caterpillar unit injectors.

Benefits for Your Workshop

- In-House Testing of CR Injectors

- Higher Diagnostic Accuracy

- Professional Test Documentation

- Future-Ready Investment

Enables full functional testing of Common-Rail injectors directly in your workshop, eliminating the need for external testing services and reducing repair lead times.

Component-level testing allows precise identification of injector faults, reducing misdiagnosis and unnecessary part replacement.

Digital storage and reporting of test results support customer transparency, fleet maintenance records, and internal quality audits.

Supports modern high-pressure diesel systems and evolving injector technologies, protecting your workshop against technological obsolescence.

More information

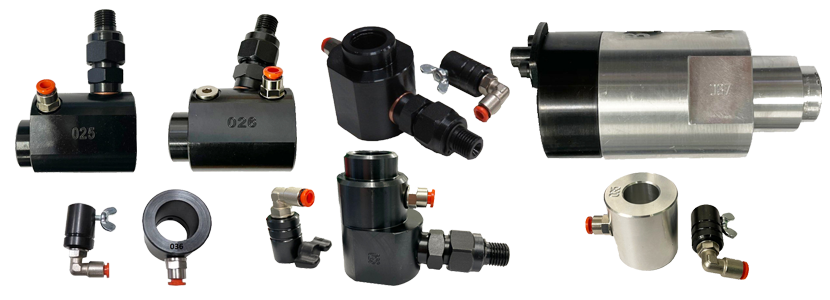

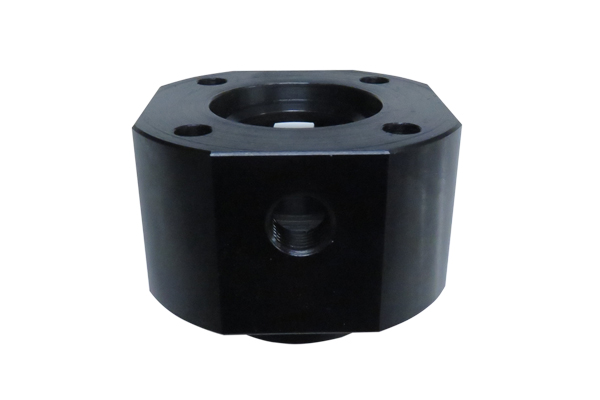

- The CRUIS test bench is designed for advanced functional testing and calibration of Common-Rail and selected unit injector systems under controlled laboratory conditions. It supports simultaneous testing of one injector with electronically regulated rail pressure up to approximately 2400 bar, allowing accurate evaluation of injector behavior across multiple operating points defined by manufacturer-specific test plans.

- PC-based software controls pump speed, injection parameters, rail pressure regulation and measurement processes, ensuring repeatable and standardized test procedures. An electronic multi-channel measurement system records injection quantity, return flow and dynamic response without the use of measuring cylinders, improving precision and reducing operator influence on results.

- The system supports injector coding procedures for Bosch, Delphi, Denso and Siemens/VDO systems, including vacuum-assisted coding for Delphi injectors and timing detection using dedicated sensors. Integrated cooling and heating circuits stabilize test fluid temperature, ensuring reliable measurement consistency during extended test cycles.

- All test results are digitally stored and can be reviewed, exported or printed for documentation, quality control and warranty purposes. The wide compatibility with automotive, commercial, agricultural and industrial diesel systems makes CRUIS suitable for high-volume professional diesel service centers and specialized injector repair workshops.

- The design of the CR test stand and the elements of its equipment meet the requirements of international standards in terms of static and dynamic parameters of ISO 4008/1 and ISO 4008/2.

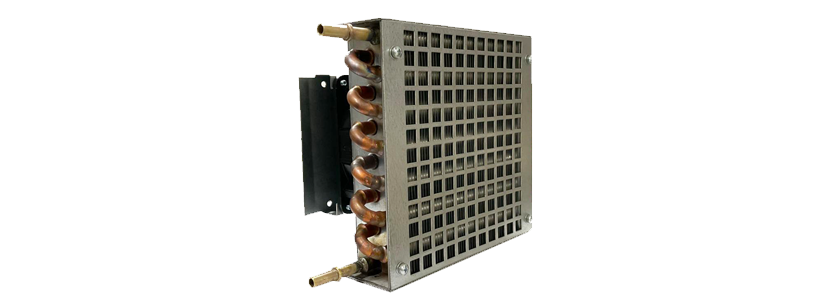

- For thermal stabilization of the test liquid in the tank, the following are used:

-

Two radiators with forced air cooling for the backflow line from the injection pump and the backflow line from the pressure accumulator (rail).

Independent refrigeration unit with air heat exchanger.

Tubular electric heater 1000 W