DL-GR7300. Grinding machine for the needles of nozzles with speed indicators

Injector nozzle grinding machine

GR-7300 — Injector nozzle grinding machine

The GR-7300-Machine for sharpening needles of atomizers and other bodies of rotation.

Not sure which additional equipment you need?

Tell us injectors you see most often — we’ll configure the machine for you.

Tell us injectors you see most often — we’ll configure the machine for you.

Supported Systems and Technical Capabilities

- Grinding machine for injector nozzles and other rotating bodies

- Processor-controlled operation with digital RPM display

- Maximum spindle speed: 7,300 RPM

- Maximum workpiece rotation speed: 1,200 RPM

- Independent speed control of spindle and rotating body

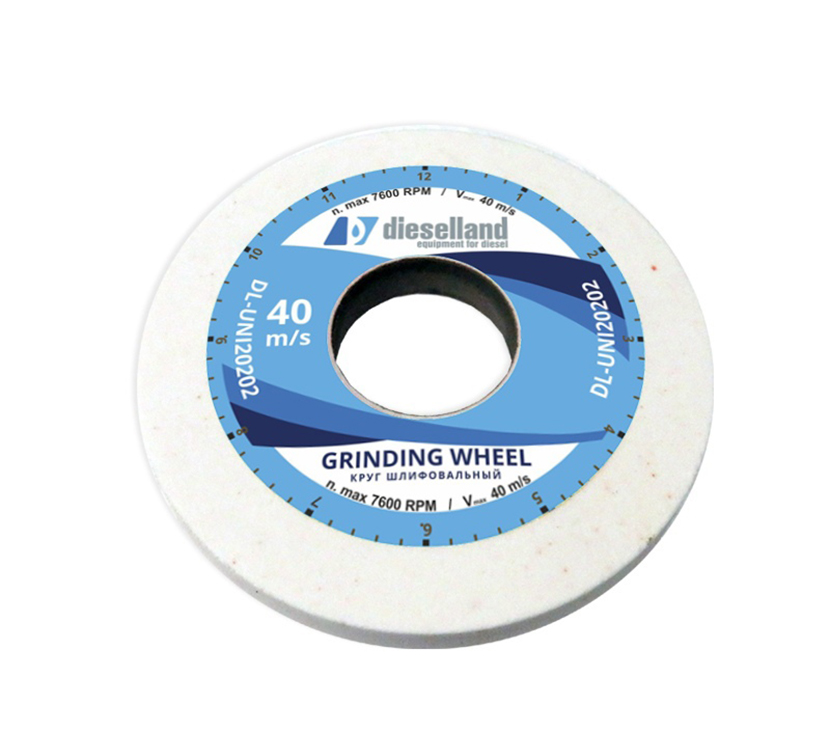

- Fine-grained electrocorundum grinding wheel for precision sharpening

Benefits for Your Workshop

- Lower cost for injector repair

- High-Precision Needle Grinding

- Full Speed Control and Monitoring

- Integrated Visual Inspection

Allows worn nozzle needles to be restored and reused instead of replaced, reducing spare-part costs and lowering the total repair cost per injector.

Ensures accurate geometry and surface finish of nozzles and small rotating parts.

Digital RPM indicators allow precise adjustment and repeatable results.

When used with the DL-UNI20025 kit, operators can inspect sharpening results in real time.

More information

- The DL-GR7300 is designed for professional sharpening of nozzle needles and other precision rotating components used in diesel and industrial applications.

- The machine is controlled by a processor, and both spindle speed and workpiece rotation speed are clearly displayed on the control panel for accurate adjustment.

- The grinding system uses a fine-grained electrocorundum wheel, providing smooth surface finish and stable sharpening quality.

- Suitable for diesel service centers, injector repair workshops, and precision mechanical service facilities.

- Optional angle meters DL-GR1080 and DL-GR1090 can be installed for precise angle measurement during sharpening operations.

- The machine is typically used together with the DL-UNI20030 kit, which includes:

-

Electronic industrial microscope

Holder and backlight

Monitor for visual inspection during sharpening