PTC-2500. Common Rail Pump Control Module

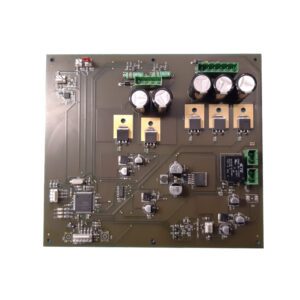

The “PTC-2520” device is designed for the supply of user-programmable control signals for the pressure regulators of the test system and injection pump of the Common Rail system to verify their operability.

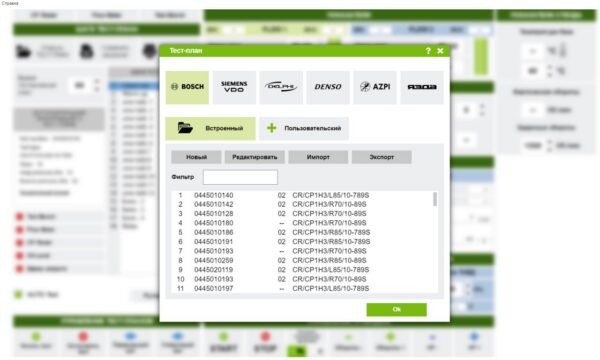

The “PTC-2520” device allows performing procedures related to testing of high-pressure fuel pumps of the Common-Rail system of various manufacturers (Bosch, Denso, Delphi, VDO (Siemens)) installed on any diesel engines of light and medium automotive traction, including high-speed engines of cars, buses, trucks and agricultural tractors.

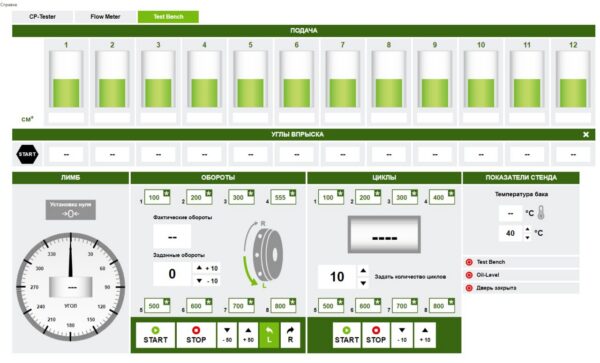

Working with the controller

The device is supplied with the software “DieselTest”.

To test CP pumps with the “PTC-2520” device, is needed a test bench with a power of 7.5 kW or more (for example SPF-708), various pump attachment devices and a pressure accumulator (rail) with pressure regulators (1 to 3 pcs.). To check the performance of the CP pumps, a backflow is measured after the pressure regulators using a flow meter ( FMDE-500).

When testing the performance of CP1 pumps, the outputs of the HIGH device are connected to the high pressure regulators (DRV) and the SENS output of which is connected to a pressure sensor.

To check the CP2 pumps, the outputs of the HIGH device connected to the high pressure regulators (DRV) are used, the SENS output of which is connected to the pressure sensor and the LOW outputs connected to the low pressure regulators (ZME) located on the pump. Also on the CP2 pump is a speed sensor to which the RPM output is connected.

The CP3 pumps use a single low pressure regulator (ZME). When testing them, you only need to connect channel 1 of the LOW output

Checking of pumps is carried out both using test plans built in the program, and with the possibility of creating their test plans and controlling pumps in manual mode.