|

*** SOLD SEPARATELY ***

|

| № |

Articles |

Name |

Desription |

Photo |

Amount |

|

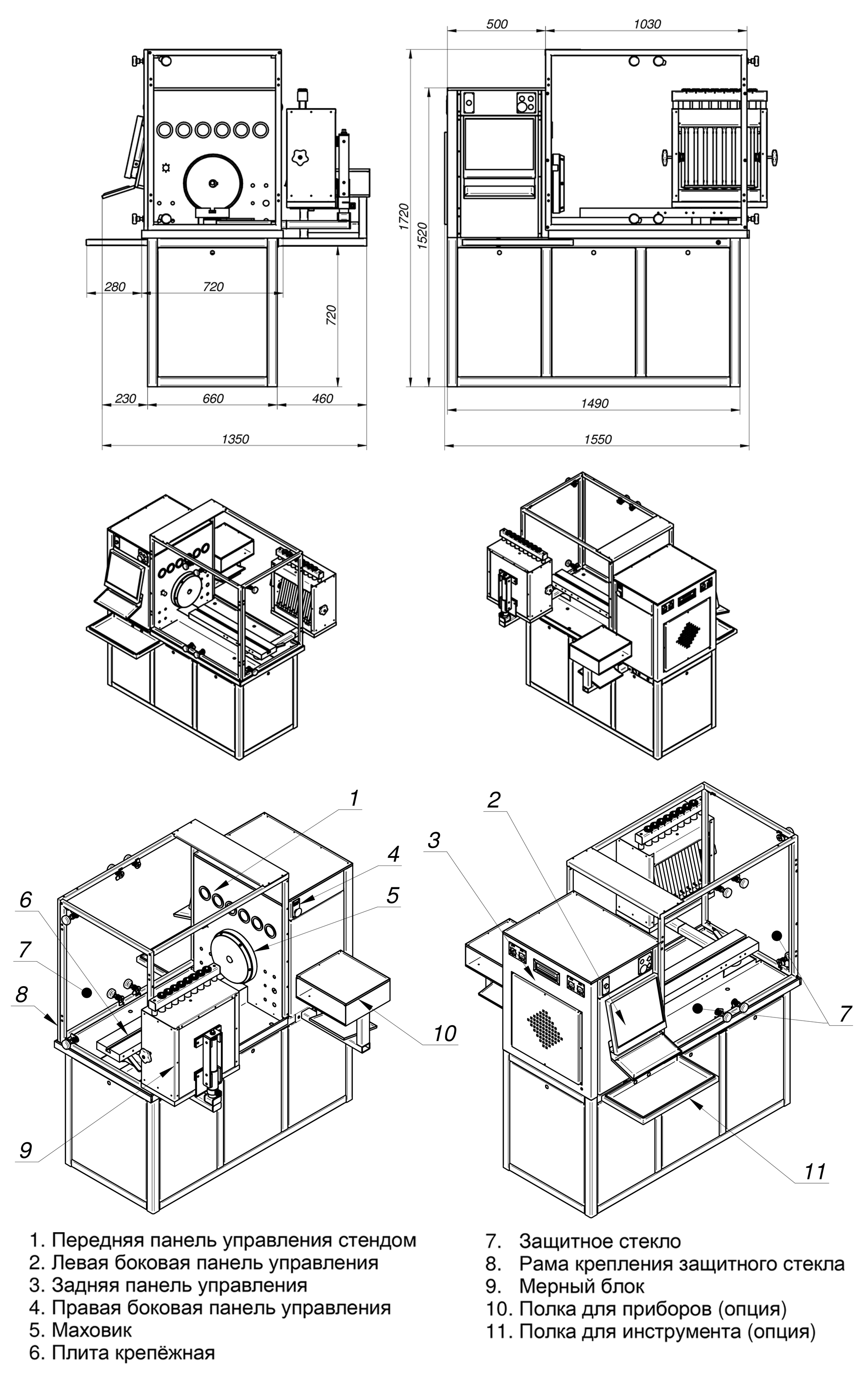

Equipment for testing high-pressure fuel pumps of the system Common Rail, VE, VP, P, PE

|

| 1 |

DL-UNI20100

|

Control rack for test benches for injectors and high pressure pumps |

The rack can move along the floor on wheels with fixation.

A PC with a keyboard and monitor or a laptop can be installed on the rack.

At the bottom of the rack there is a shelf for the printer, which is closed with a door with polycarbonate glass.

The protective door for the printer slides inside the rack, which creates additional convenience for accessing the printer.

In the middle part of the rack there are two shelves for installing control devices for various fuel systems.

Provides convenient access to all equipment installed on this control rack. |

|

1 pc |

| 2 |

PUMP TEST.02 |

High pressure pump testing equipment Common-Rail |

Device «PTC-2520» allows testing diesel high-pressure fuel pumps of the CommonRail system by supplying the necessary signals specified by the user to control the valves-regulators of the high-pressure fuel pump and pressure regulators of the test system.

Device «FMDE-520» The 2-channel fluid flow meter is responsible for checking the performance of diesel injection pumps (high pressure fuel pumps) of the Common Rail system. |

|

1 set |

| 3 |

DL-ORV002 |

Cooling rack |

Type – radiator-fan

2 heatsinks with fans

Power 2 x 38 W

Power supply 230 V 50 Hz |

|

1 pc |

| 4 |

DL-ORV013 |

Forced air coolers |

For cooling the overflow of the tested high pressure fuel pump.

*** The photo is illustrative, on the carrier rack behind the electric box, both one- and two-section radiators can be placed to cool the supply and / or return flow of the tested high-pressure fuel pump |

|

1 pc |

| 5 |

DL-MSP |

Maslostation mobile for stands |

Operating pressure 0-10 bar

Productivity at a pressure of 3 bar – 150 liters / hour

Fine filter 10 µm

Tank 20 liters

Power supply 380 V 50 Hz

Power consumption 0.37 kW |

|

1 pc |

| 6 |

PTC-2520 |

Common rail high prerssure pumps control module |

Controller «PTC-2520» is designed to supply user-programmed control signals to pressure regulators of the test system and high-pressure fuel pumps of the Common Rail system to test their performance. |

|

1 set |

| 7 |

FMDE-520 |

Digital dual-channel flowmeter |

Dual-channel flowmeter “FMDE-520” designed to test and verify the performance of high pressure diesel fuel pumps (TNVD) of the Common Rail system. |

|

1 set |

| 8 |

DL-UNF20400 |

A set of sedimentation filters for checking high-pressure fuel pumps at the stand |

For filtering the test fluid in the supply and return lines from the tested injection pump |

|

1 set |

| 9 |

DL-UNI50126 |

15 µm fluid filter with 3/8″ outlets |

It is used to clean the test liquid in the lines for measuring flow and return flow. |

|

1 pc |

| 10 |

DL-UNF20110 |

Liquid fine filter (element) 10 µm |

It is used for fine purification of the test liquid entering the booster pump of the tested injection pump |

|

1 pc |

| 11 |

DL-UNF20103 |

Liquid fine filter (element) for 3 microns |

It is used for fine purification of the test liquid entering the booster pump of the tested injection pump |

|

1 pc |

| 12 |

DL-UNF20124 |

3 µm liquid fine filter |

It is used for fine cleaning of the test fluid in the tested high pressure fuel pump in the “high pressure fuel pump-FilterIN-FilterOut-high-pressure fuel pump” circuit |

|

1 pc |

| 13 |

HPFP VE / VP / P / PE |

Equipment for testing high pressure fuel pumps VE / VP / P / PE |

This section contains the necessary equipment for connecting various high pressure fuel pumps, couplings, sensors, flanges and brackets |

|

by order |

| 14 |

HPFP COMMON RAIL |

Equipment for testing common rail high-pressure fuel pumps |

This section contains the necessary equipment for connecting various high pressure fuel pumps, couplings, sensors, flanges and brackets |

|

by order |

| 15 |

Equipment for mounting the hydraulic line |

Adapters, fittings, fittings |

This section contains the necessary equipment, cables, adapters, tubes, fittings for connecting and testing common rail injectors |

|

by order |

|

Equipment for testing common rail injectors, HEUI

|

| 16 |

FLAGMAN-CODE

/

FLAGMAN-FULL

/

FLAGMAN-FLOW

|

Test kit for CR injectors with and without coding.

*** 3 configuration options are available, in which the rack with the measuring unit is equipped with a controller as a device CR-TESTER CRT-5040 operation of Common Rail injectors and the vacuum system (vacuum) for coding Delphi injectors |

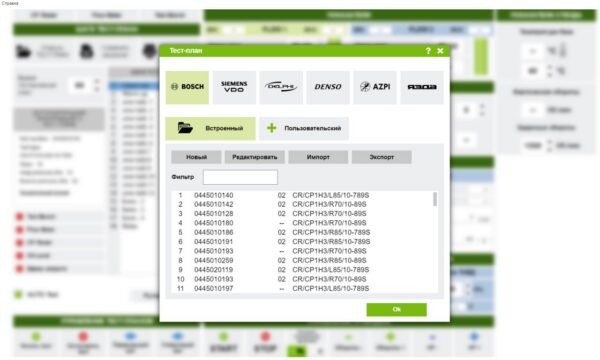

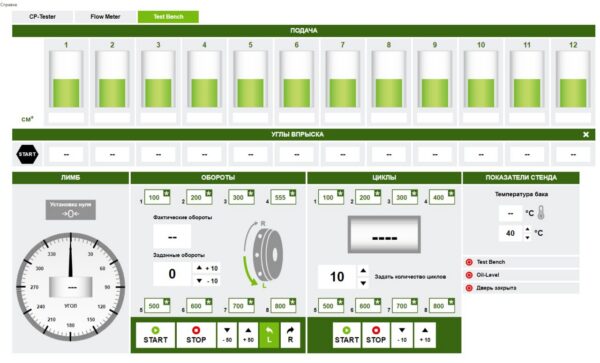

The complex is designed for diagnosing common rail injectors manufactured by Bosch, Denso, Delphi, Siemens VDO at the stand. The injectors are checked by applying a control signal from the controller to the tested injectors and maintaining the required pressure in the system according to the selected test plan.

Please note that this complex can be installed to any injection pump test stand of any manufacturer.

The complex consists of a measuring unit FLAGMAN-FLOW and controller CR-TESTER CRT-5040. The complex is also equipped with a vacuum system for coding Deiphi C2i, C3i, C4i injectors.

The measuring unit is divided into 2 sections designed to measure the flow of test liquid through the nozzles in the “supply” and “return” lines, respectively. Each section can measure the strait in 4 channels. A temperature sensor of the incoming liquid is installed at the inlet to each meter. This temperature is displayed in the CASCADE program. Connection to the measuring unit is carried out using Teflon tubes included in the delivery. |

|

1 set

/

1 set

/

1 set |

| 17 |

CR-TESTER CRT-5040 |

Common Rail fuel system test controller |

Device “CR-TESTER CRT-5040” designed for diagnosing CommonRail system injectors manufactured by Bosch, Denso, Delphi, Siemens VDO at the stand. The injectors are checked by applying a control signal from the controller to the tested injectors and maintaining the required pressure in the system according to the selected test plan. |

|

1 set |

| 18 |

Equipment for testing injectors COMMON-RAIL system |

Equipment for testing Common Rail injectors |

This section contains the necessary equipment for connecting various Common Rail system injectors, pressure accumulators, holders, adapters, pressure gauges, etc. |

|

by order |

| 19 |

Adapters for testing cargo injectors of the COMMON-RAIL system |

Truck injector test adapters |

This section contains various adapters, cables, adapters, fittings for connecting and testing cargo injectors of the Common Rail system |

|

by order |

|

Equipment for testing unit injectors and pump sections UIS/UPS

|

| 20 |

CAMBAT-FULL-SET

/

CAMBAT-FULL

/

CAMBAT-FLOW

|

Equipment for testing and checking Unit-Injectors and Pump sections of the UIS/UPS system with a mechanical part

*** There are 3 configuration options available, in which the measuring stand is equipped as a device with a controller for the operation of unit injectors “UIS TESTER Multi-CAM” and CAM-BOX 2. |

Designed for diagnosing unit injectors and pump sections manufactured by Bosch, Denso, Delphi, Siemens (VDO) at the stand. Testing of pump injectors is provided by supplying a control signal from the equipment to the tested pump injectors and maintaining the required pressure in the system according to the selected test plan. |

|

1 set

/

1 set

/

1 set |

| 21 |

CAM-BOX 2 MASTER |

Equipment for testing unit injectors and pump sections PLD (UIS/UP SYSTEM) |

Equipment СAM-BOX2 MASTER includes 2 parts:

CAM-BOX 2 MECHANIC mechanical part;

OS 21-01 electronic part, «UIS TESTER Multi-CAM».

CAM-BOX 2 is mounted on a 125 mm stand. For stands of other standards, an adapter plate is used, which is not included in the delivery set.

CAM-BOX 2 in the basic configuration allows you to perform tests for unit injectors from BOSCH for Volvo cars and some versions of Iveco. For testing other unit injectors and single pumps, other clamp adapters are available and can be ordered separately.

|

|

1 set |

| 22 |

CAM-BOX 1 FORCE |

Equipment for testing unit injectors (UIS/UP SYSTEM) |

Equipment CAM-BOX 1 FORCE includes 2 parts:

1) mechanical part, which is called «CAM-BOX 1»

2) electronic part, which is called «UIS TESTER Multi-CAM»

The mechanical part (base) is installed on a stand of 125 mm standard. It allows you to perform tests for Volvo and some versions of Iveco.

To test other models of unit injectors, other clamps and adapters are used, which can be ordered separately. |

|

1 set |

| 23 |

UIS TESTER Multi-CAM |

Electronic part for controll and test

injector pump |

Test and Verification Instrument

unit injector performance (UIS)

and individual fuel pumps

(pump sections) high pressure with

high pressure solenoid valves

pressure (UPS). |

|

1 set |

| 24 |

CAM-BOX 2 MECHANIC |

Mechanical part for testing unit injectors and pump sections PLD ( UIS/UPS SYSTEM). |

CAM-BOX 2 establishes on the stand of the standard 125mm. For stands of other standards, an adapter plate is used, which is not included in the delivery set.

CAM-BOX 2 in the basic configuration allows you to perform tests for BOSCH unit injectors for Volvo cars and some versions of Iveco. For testing other unit injectors and single pumps, other clamp adapters are available and can be ordered separately. |

|

1 set |

| 25 |

CAM-BOX 1 |

Mechanical part for testing unit injectors (UIS/UP SYSTEM). |

CAM-BOX 1 establishes on the stand of the standard 125mm. For stands of other standards, an adapter plate is used, which is not included in the delivery set. In the basic configuration, the equipment allows you to perform tests for BOSCH unit injectors for Volvo cars and some versions of Iveco. |

|

1 set |

| 26 |

UNIT INJECTOR UIS / UPS FOR CAM 2 |

Clamp adapters and accessories for CAM-BOX 2 |

The section contains the necessary equipment for connecting various types of unit injectors, couplings, sensors, flanges for switching connections CAM-BOX 2 |

|

by order |

| 27 |

UNIT INJECTORS UIS / UPS FOR CAM 1 |

Clamp adapters and accessories for CAM-BOX 1 |

The section contains the necessary equipment for connecting various types of unit injectors, couplings, sensors, flanges for switching connections CAM-BOX 1 |

|

by order |