The CR-JET Equipment allows you to perform procedures related to testing and checking Common-Rail injectors of various manufacturers (Bosch, Denso, Delphi, VDO (Siemens) Cummins, Caterpillar, AZPI).

The design of the CR Equipment and the elements of its equipment meet the requirements of international standards in terms of static and dynamic parameters of ISO 4008/1 and ISO 4008/2.

The test fluid of the ISO 4113 standard is used as a working fluid in the test bench. The high-pressure source is a high-pressure fuel pump , which is driven by a 4 kW, 1500 rpm asynchronous motor. As a feed pump, a gear pump is used, which is integrated into the injection pump housing and has the same drive.

In the basic version, the test bench has test plans without the possibility of encoding injectors.

Additionally, you can order:

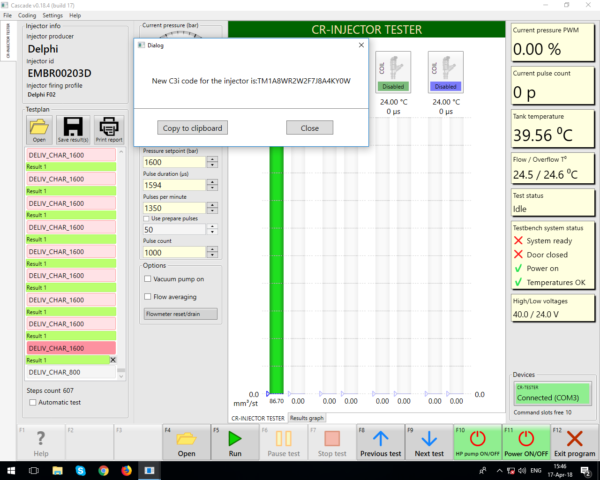

1. Hardware and software for coding of injector Delphi C2I and C3I

2. Software for coding of electromagnetic and piezo injectors BOSCH

3. DENSO Injector Coding Software

4. Software for coding of piezo injectors SIEMENS VDO

For coding Delphi injectors, a device is installed that allows you to create a vacuum in the injector backflow line. The vacuum-creating device kit includes an electric-liquid pump, a Venturi tube with a tee, switching adapters and fittings with Teflon connecting tubes. The device is installed on the partition, which is located in the lower part of the test bench, above the refrigeration unit. Also in the working (test) zone, the pressure gauge measuring rarefaction with an electrovalve providing access of the rarefaction to the injector is installed at the top right. In this case, the vacuum is regulated by a throttle valve installed under the monitor on the left. When coding Delphi injectors in the test bench, a sensor is used that determines the time of the beginning of injection.

The Equipment has a low noise level. When starting the high pressure pump, its smooth promotion is ensured due to the use of a Shneider frequency converter in the test bench .

For thermal stabilization of the test fluid in the tank are used:

-two radiators with forced air cooling for the backflow line from the high pressure fuel pump and the backflow line from the pressure accumulator (rail).

-independent refrigeration unit with air heat exchanger 1000 W -tubular electric heater

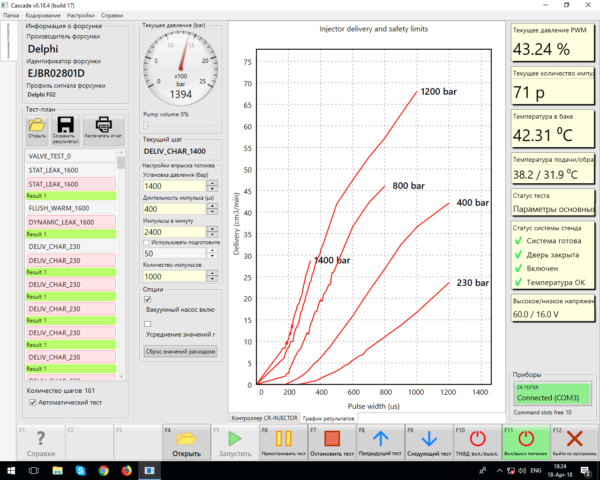

Operating pressure up to 2400 bar.

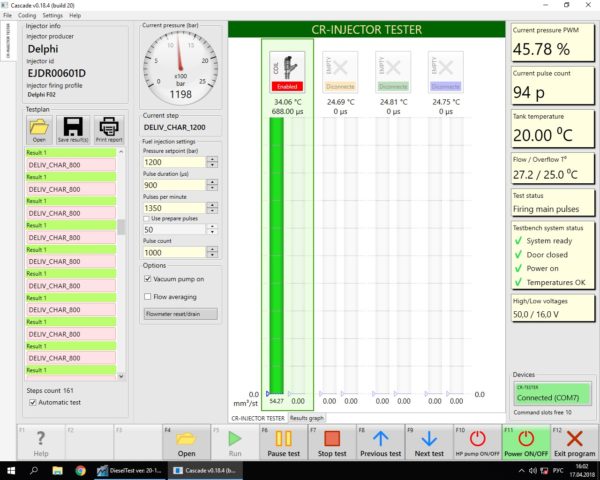

The Equipment has an electronic measuring system with the ability to simultaneously check of 4 injectors.

A software with test plans is included in the set of delivery. The software has a convenient interface in Russian and English.

Software updates, including new test plans, are released twice a year and are provided free of charge.