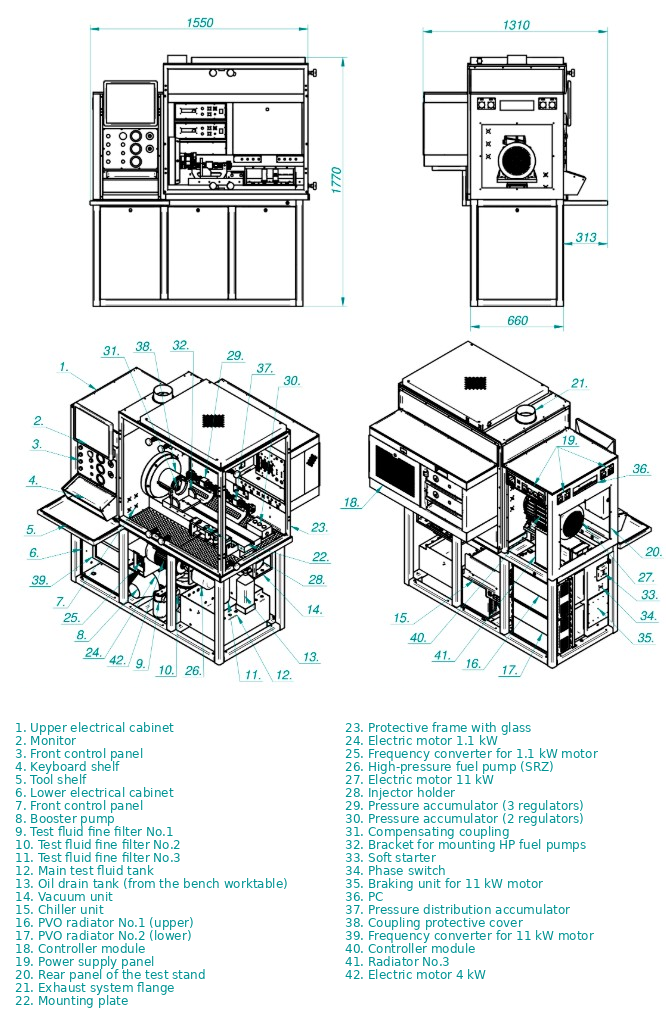

CR-TEST-4E — Common-Rail Injector and Pump Testing

CR-TEST-4E is a high-performance Common-Rail testing system designed for diagnosing, checking, and evaluating the operation of modern diesel Common-Rail injectors and high-pressure pumps used in cars, trucks, agricultural machines, and industrial engines.

Tell us pumps and injectors you see most often — we’ll configure the bench for you.

What CR-TEST-4E Does?

- The system enables your workshop to reliably test and verify the performance of:

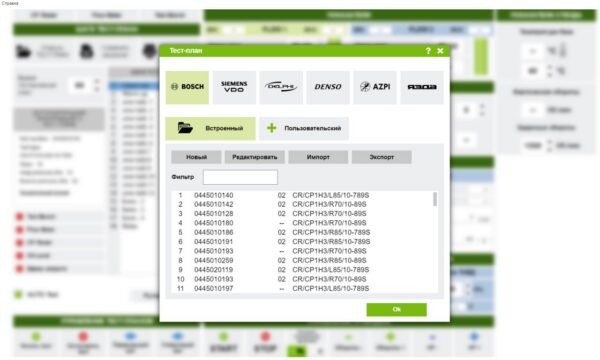

- Common-Rail injectors from Bosch, Denso, Delphi, VDO Siemens, Cummins, AZPI, as well as HEUI Caterpillar unit injectors.

- Common-Rail high-pressure pumps, including CP1, CP2, CP3, HP2, HP3, HP4, DFP series

Benefits for Your Workshop

- In-House Testing of CR Injectors and Pumps

- Professional Test Documentation

- Future-Ready Investment

Enables full functional testing and coding of Common-Rail injectors and high-pressure pumps directly in your workshop, eliminating the need for external testing services and reducing repair lead times.

Digital storage and reporting of test results support customer transparency, fleet maintenance records, and internal quality audits.

Supports modern high-pressure diesel systems and evolving injector technologies, protecting your workshop against technological obsolescence.

More information

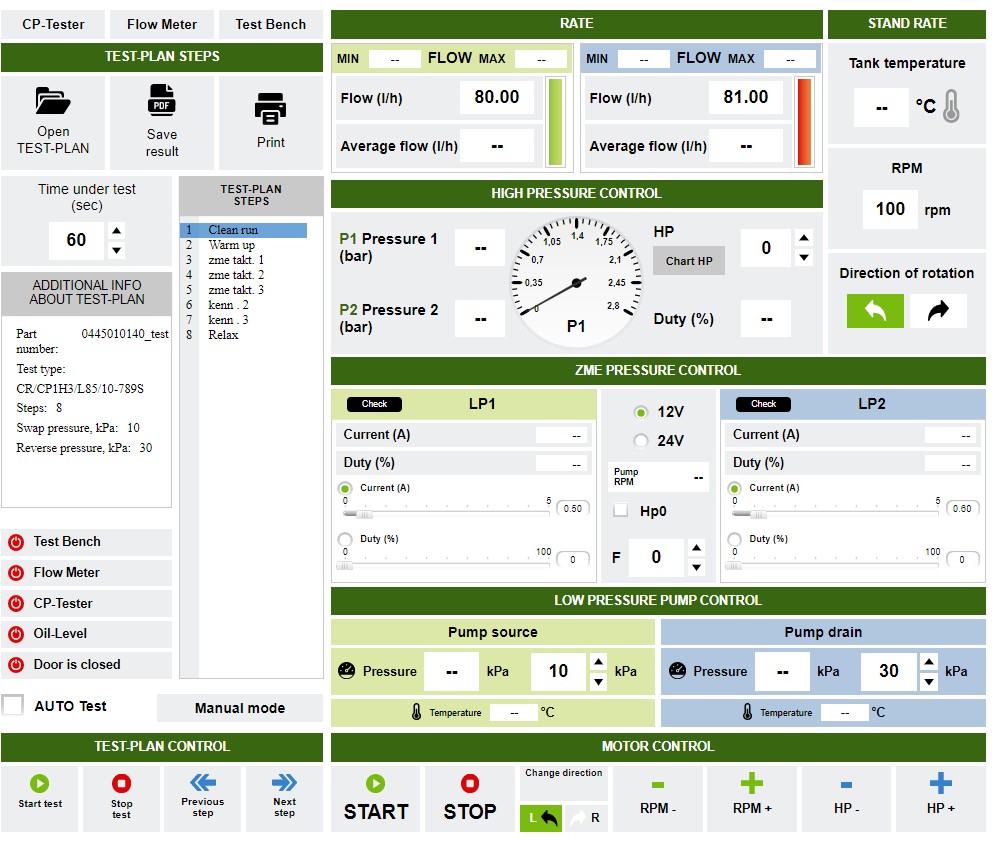

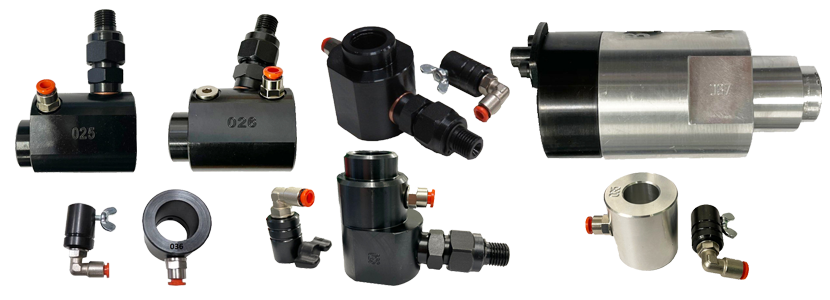

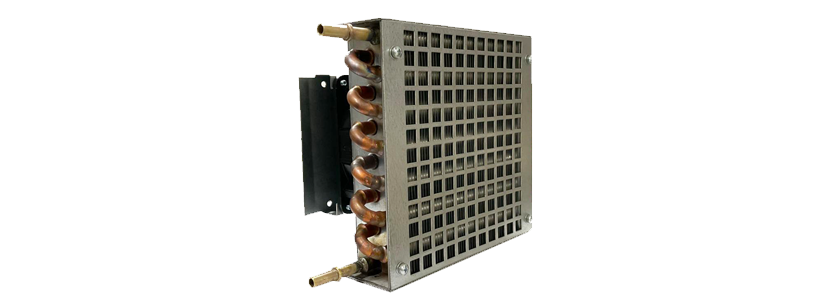

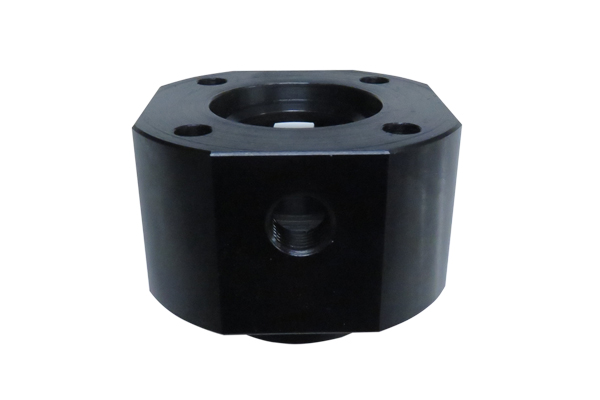

- The CR-TEST-4E test bench is designed for functional testing of Common-Rail injectors and high-pressure pumps with electronically controlled rail pressure up to approximately 2400 bar, allowing evaluation of component behavior under operating conditions comparable to those in modern diesel engines. The system supports testing of Bosch, Denso, Delphi and optional Siemens/Continental components, including injector flow rate, return flow, pressure response, and dynamic operation at multiple load points defined by manufacturer-specific test plans.

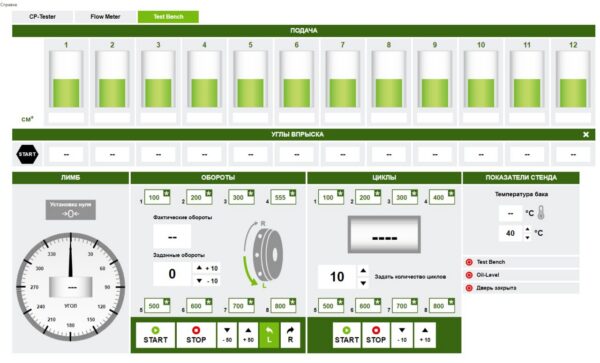

- PC-based control software manages pump drive speed, rail pressure regulation and injection parameters, while an electronic multi-channel measuring system records delivery and leak-off quantities without manual measuring cylinders, improving accuracy and repeatability. The bench allows simultaneous testing of up to four injectors, enabling comparison of performance between cylinders and detection of imbalance. High-pressure pump testing includes evaluation of delivery capacity, pressure stability, and functionality of pressure control valves and metering units.

- Fuel temperature and pressure are continuously monitored to ensure stable test conditions and reliable results, and digital storage of test data enables verification after repair, quality control, and documentation for warranty or fleet maintenance records. This allows workshops to perform complete verification of Common-Rail components before installation, reducing repeat failures and ensuring compliance with OEM performance tolerances across automotive, commercial vehicle, agricultural and industrial diesel applications.