The FLAGMAN Code complex is designed for diagnosing CommonRail injectors manufactured by Bosch, Denso, Delphi, Siemens VDO at the bench. The injectors are checked by applying a control signal from the controller to the tested injectors and maintaining the required pressure in the system according to the selected test plan.

Pay attention, that this complex can be installed to any injection pump test stand of any manufacturer.

The complex consists of a MUFI-CR measuring unit and a Flagman CRT-5040 controller. The complex is also equipped with a vacuum system for coding Deiphi C2i, C3i injectors, *C4i(special). The vacuum-creating device kit includes an electric-liquid pump, a Venturi tube with a tee, switching adapters and fittings with Teflon connecting tubes.

The measuring unit is divided into 2 sections, designed to measure the flow of test liquid through the injectors in the “flow” and “overflow” lines, respectively. Each section can measure the strait in 4 channels. A temperature sensor of the incoming liquid is installed at the inlet to each meter. This temperature is displayed in the CASCADE program. Connection to the measuring unit is carried out using teflon tubes included in the delivery.

The complex provides:

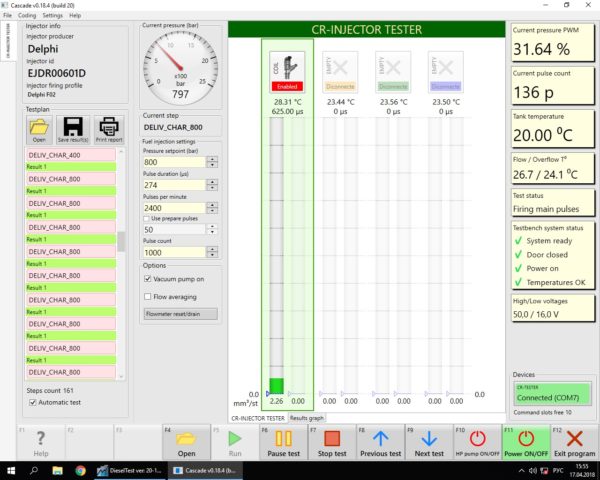

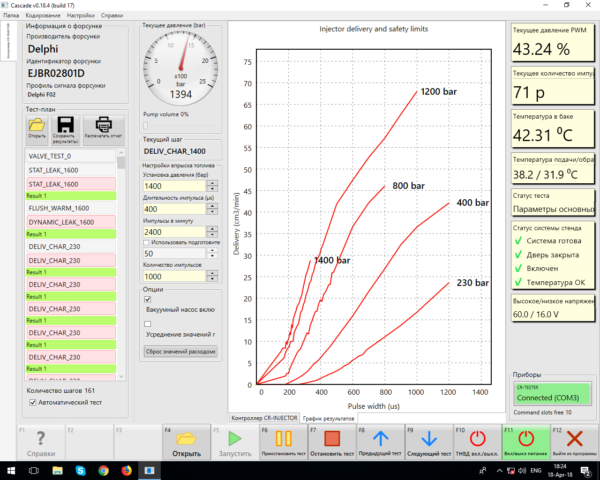

- at the same time managing of 1-4 injectors;

- the ability to assign a correction code to BOSCH ISA, IMA injectors;

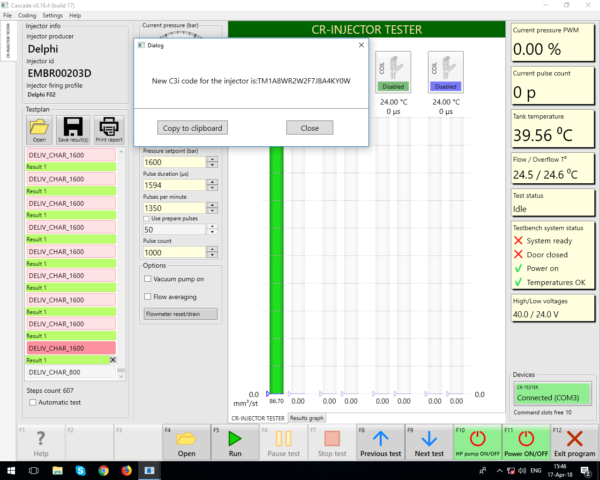

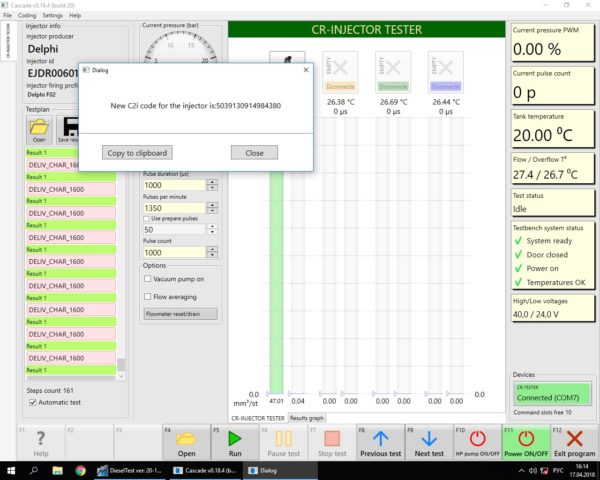

- the ability to assign a correction code to DELPHI C2i, C3i injectors, (C4i special);

- the ability to assign a correction code to Denso injectors;

- the ability to assign a correction code to VDO injectors (Siemens);

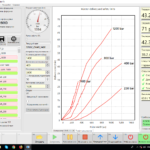

- pressure control in the system in manual and automatic mode;

- control of electromagnetic injectors of a light series from a voltage of 14 V;

- control of electromagnetic injectors of a cargo series from a voltage of 28 V;

- control of piezoelectric injectors;

- disabling control in the absence of a protective screen in the test area;

- stop control of the drive of the bench injection pump after the end of the test;

- temperature measurement in the tank;

- measurement of injector backflow temperature;

- measurement of injection start time;

- cooler and heater control;

- control of the measurement flow and overflow injectors.

* Functions are additional options and are not included in the basic version of the complex!

Specifications |

|

| Count injectors which tested at the same time | 4 |

| Supply of valves in the measuring block of injectors | 24 V |

| Injector opening pulse frequency | 60 – 1500 min-1 |

| Injector opening impulse duration | 100 – 3000 mks |

| Temperature control test liquid for checking injectors | for each injector |

| Number of measurements sensors in MUFI-CR | 2 |

| Speed of measurement of the measuring block of injectors | 0,01 l/min-0,5 l/min |

| Measurement error (cars) 0.15 mm3 -85 mm3 | no more 1% |

| Measurement error (trucks) 0.15 mm3 – 400 mm3 | no more 1,5% |

| Resolution MB injectors | ~ 0,1 mm3 /1 cycle (injection) |